Waste household appliances dismantling refrigerant recycling machine

Product model:

DKT-900

Product introduction:

It is used for recycling refrigerant (Freon) before dismantling waste air conditioner, refrigerator and other refrigeration appliances

Problems affecting the output and benefit of dismantling production line of waste air conditioner and refrigerator

1.Spraying liquid phenomenon

2.The recycling is not clean

3.Slow recovery speed

4.If the cylinder cannot receive liquid, an effective ledger cannot be established for control

5.Liquid spraying occurred from the end of fluorine collection to the dismantling station

6.The workers did not have enough understanding of the equipment use and freon performance

7.The enterprise lacks a complete set of operation procedures and control of fluoride removal

8.Imperfect supporting device at work station, phenomenon of pipe dragging

According to the above problem and dismantling companies have, for each enterprise status field to make suitable for their own solution, continue to escort for air conditioning refrigerator disassembly production line, put an end to deduct losses, increase staff awareness really fulfill the clear water, blue sky environmental protection environmental protection concept will each component material, piping layout layout for the enterprise beautiful and convenient, you only need a phone call and leave the rest to us

Product standard configuration characteristic introduction

1) The core compressor adopts the high-power oil-free open-type multi-stage piston compressor

2) The whole machine is designed and manufactured strictly in accordance with long 24-hour production operation conditions.

3) Applicable to a variety of refrigerants: R22/R134A/R410A/R407C, etc

4) The equipment is equipped with a large-capacity negative pressure oil separation device to ensure that each station system is always in a high negative pressure state

5) The negative pressure of recovery can reach -0.09mpa, and the recovery is complete

6) Multi-stage oil separation, and the purification unit carries out purification treatment of refrigerant to ensure the reuse to create value

7)Multi-interface design is based on output usage and production line layout

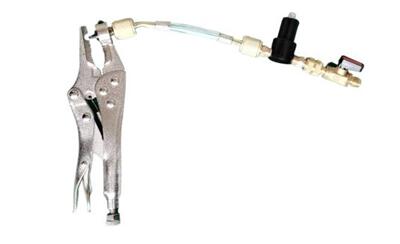

8) Type of combined quick joint, type of original acupuncture pliers is optional

9) Real-time detection of pressure state by fluid pressure detector, industrial-grade design resistant to knock

10) Multi-station interface design, which can be recycled at the same time (15-30 interfaces)

11) The whole machine is designed in accordance with environmental protection requirements without leakage, and the operation of multiple safety protection devices is stable and safe

12) stainless steel industrial-grade heat exchanger is strong and durable

13) Automatic detection of non-condensing gas emission device is used to discharge the air accidentally mixed with the storage tank to ensure the optimal operation of the device

Specifications: